At Sonderen Packaging, we work closely with all of our customers to design boxes that are the right fit for their product, their brand, and their budget. Here are a few of the considerations that will make a big impact on the cost of your paperboard packaging.

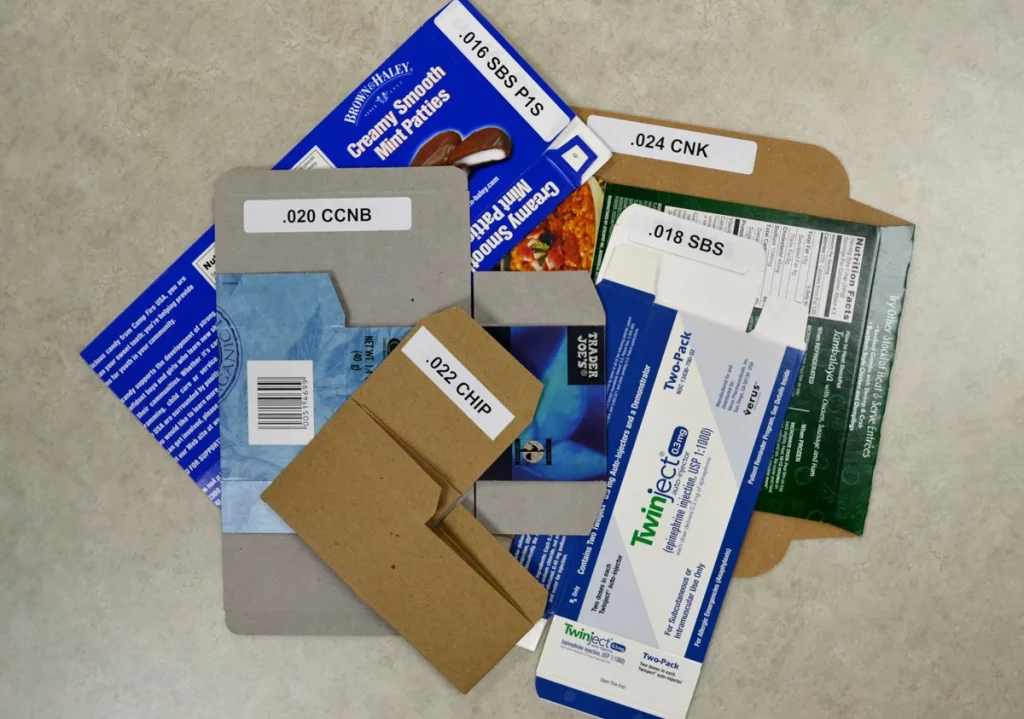

1. CHOOSE THE RIGHT CARTON MATERIAL

“I work with a lot of smaller customers that are just trying to get off the ground, so one of my jobs is to point them in the direction of the most cost effective packaging solution,” says Keva, our co-president and account executive. “A lot of the time, I’ll start with the type of material they need.”

There are many different grades of paperboard, so you will want to select one that’s sturdy enough for your packaging needs and balances your budget and your company brand.

“We offer a non-recycled material with just virgin fibers in it: that’s our most expensive. Then we have materials with recycled content, and there are other grades as well,” says Keva. “I try to work with customers on what their brand is and how their packaging will support their brand. If it’s a pharmaceutical product or a high end product, they really should go with the virgin materials because that is going to reflect their brand the best, but others I’ll point in the direction of something that is a lower cost. There are some things that you shouldn’t make concessions on in your packaging, but material is one area that customers can save a little money.” Regardless of the material you choose, it is all recyclable and sustainable. We love that about paperboard.

2. LIMIT YOUR COLORS

Limiting the number of colors in your design can drastically reduce the cost of your packaging, especially your start-up cost. Each color requires a printing plate. The printing plates get reused in future print runs until your design changes, but the upfront cost is sometimes tough for fledgling companies.

“Graphic designers sometimes go all out and design something that is six colors that we could really do in four and achieve the same kind of look,” says Keva. “Sometimes we can even change a four color design to a two color, sometimes we can screen back a color and play with that. In most cases, you also have the white of the paperboard as a freebie. We work with our customers so they understand their options and they know where the costs are coming from and where they’ll start multiplying. They can then talk to their graphic designer and say ‘this is our goal, we want to keep it at three colors, be creative.”

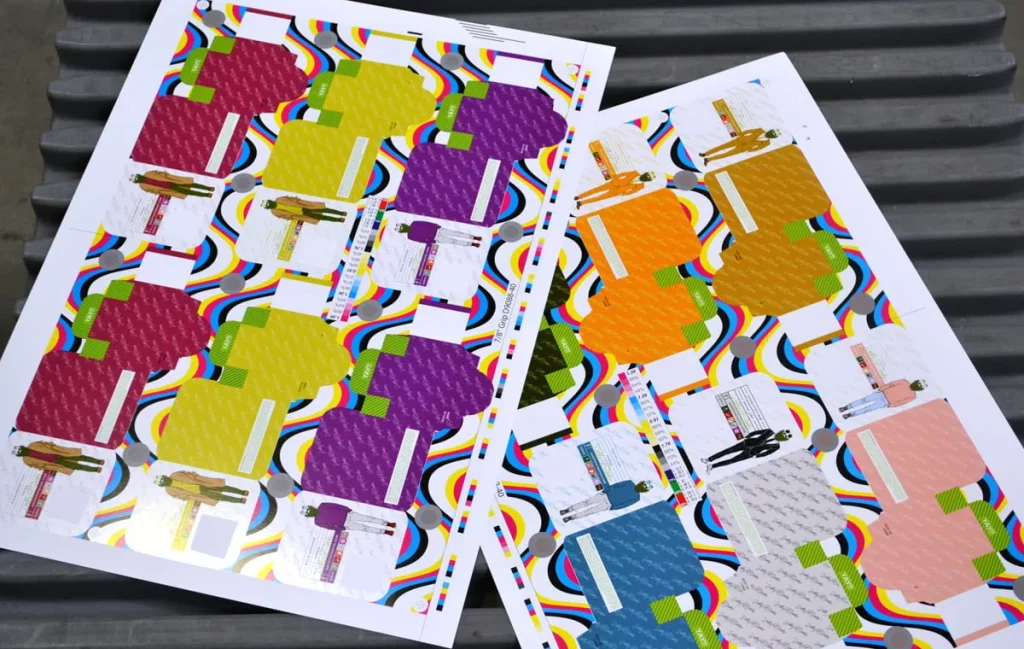

3. PLAN FOR COMBINATION RUNS

If you’ve got a variety of products, or a product with a variety of colors or flavors, you can really see costs start to multiply. If cost is a concern, it is advisable to make a generic box that can have a variety of labels applied to it, or there are design and planning decisions that can make printing multiple designs more affordable.

“If a customer really wants to print boxes for each flavor, we’ll work with them to create a combination run,” says Keva. “That means, instead of running each flavor on its own separate set of printing plates, we try to make the ratios of the quantities work so that we can run them on the same set of printing plates and print them at the same time.”

A four color job with five varieties would then potentially require only four printing plates instead of twenty!

“That’s another thing that the graphic designers need to be made aware of, is the cartons all need to be the same color scheme so they can be batch run,” says Keva. “That’s one of the reasons that four color process is so great to design in. Cyan, magenta, yellow, and black; those will really do the trick for most of our customers’ needs. That’s definitely something I recommend if there are going to be multiple kinds or flavors, which can get really pricey otherwise.”

4. MAKE SURE YOUR ARTWORK IS PRESS-READY

Prepress costs can add up quickly if your artwork files need to be fixed or changed. Also, we find that packaging seems to be the last piece of the puzzle for many projects so we are always working with tight deadlines. If you artwork is built correctly, a lot of precious time will be saved.

“We send our customers a carton design best practices sheet that they can share with their graphic designers,” says Keva. “If the graphic designer can follow some very simple guidelines on how to design their files so they come to our prepress department ready to go, we won’t have to spend a lot of time making them press-ready, which will save money.”

Much can be saved with thorough proofing as well. Catching a typo or making a design change after prepress has begun their work may end up duplicating costs and can really hurt your budget.

“If the files go through prepress and they’re ready to print and the customer then notices, oops, there’s a typo, the process starts over again and more time and money is allocated to the project. In several instances a customer may have only ever looked at the designs on a screen. You just seem to be able to catch more when you’re looking at a proof that’s been printed out,” says Keva. “That’s something we really recommend: always print out a proof if you can, before sending us the files.”

5. TALK TO YOUR PRINTER FIRST

It’s easy to get excited about how your packaging is going to look, but talk with your printer so you can understand their capabilities before spending money on graphic design. We prefer to work with our customers on structural design first, and then we can supply your graphic designer with those die lines as well as our design best practices guide.

“Everything we do is custom, we don’t have any stock boxes. There are certain designs that may run faster on our machines and save a little money there, but you also have to consider the ease of packing the product into the box when choosing your package design. After we finalize the structural design, we can run a quote for what a two color or a four color job would cost, etc,” says Keva. “A lot of designers will want to do foil, or emboss, and specialty coatings, and that’s great and we can do it, it’s just there’s a cost to it. The majority of the time we end up quoting projects a couple of different ways, just so our customers have a chance to dial in what they really can and cannot live without.

“We spend several hours with prospects before we even get a job, most of that time is spent explaining our process, creating sample cartons, and educating folks by giving tours of our facility. Custom packaging is complicated. Our goal is to make it less daunting by partnering with our customers so they feel confident in their packaging decisions. We want to be there for them and help them get started,” says Keva. “We are here to be a resource to find the perfect packaging fit for your product, your brand, and your budget.”

Contact us to discuss your custom paperboard packaging project.